-

Empty cart

No products in the cart.

Return to Shop

Description

Description

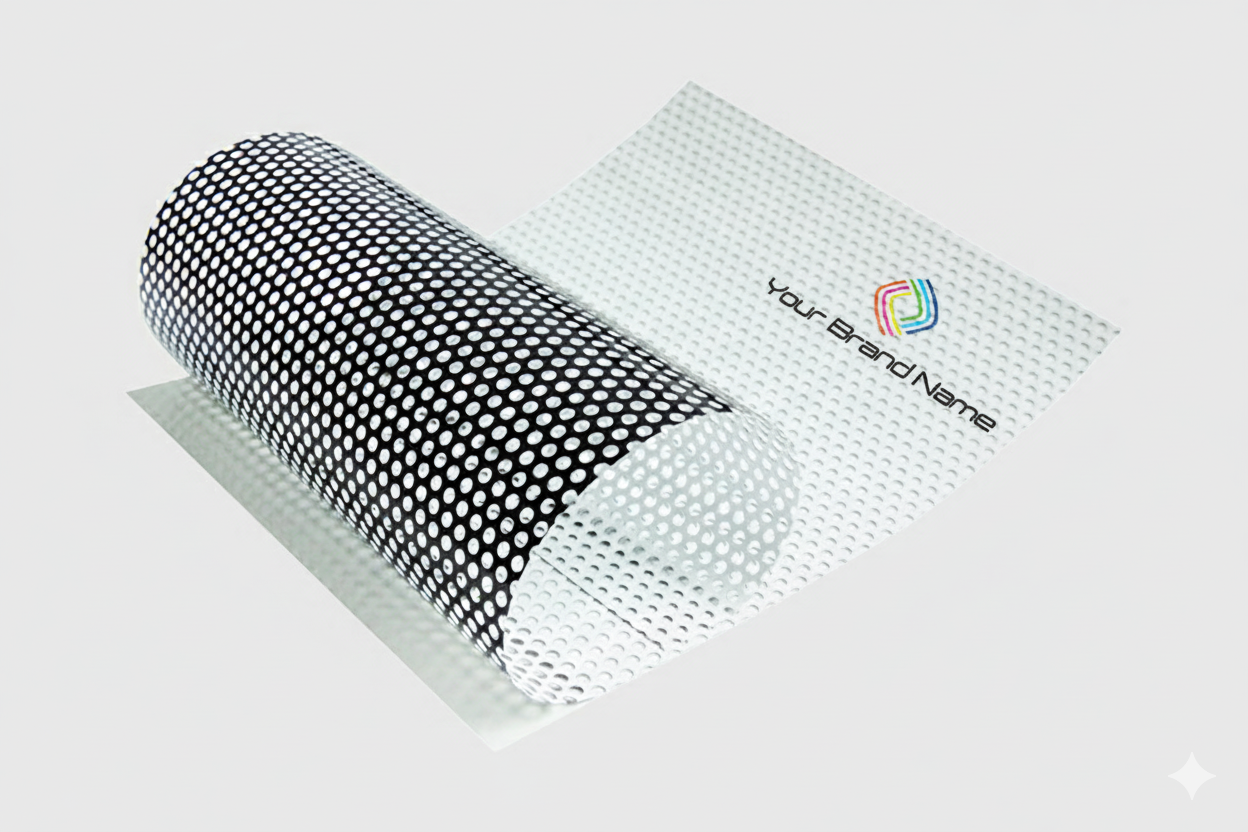

The surface to be printed on is white. This is because a white background yields better printing results, ensuring the background doesn’t show through the applied inks. The adhesive side is black. This is to ensure that when looking out from inside a glass surface with one-way vision applied, it’s not apparent that there is any application on the glass. The general perception is that glass is black, so the adhesive surface is manufactured in black. Through techniques applied to glass surfaces, building wrapping procedures can be done in a way that allows viewing the outside from inside the building. Previously, when attempting to wrap glass-surfaced buildings, the results were not very appealing because the material placed on the glass significantly restricted the view from both outside-in and, more importantly, inside-out. However, with one-way vision printing, the ability to see outside from within the applied surfaces has emerged. When viewed from outside, the desired advertisement image is displayed clearly and in high quality, while seeing inside the building is completely impossible. With standard workmanship, image quality can slightly decrease in very bright light when viewed from outside, but generally, it provides a minimum of 80-85% image visibility. When looking from inside out, there might be a 15-20% loss, but these rates are not concerning and provide quite effective results.

Where is One Way Vision Printing Used?

One-way vision printing is used on glass surfaces. It is suitable for use in any area with glass surfaces you can think of. Applying it as a wrap to the exterior facades of glass-covered buildings is its most preferred application. Additionally, this technique is frequently used for logos on partition glass and text on shop windows.

What are the Advantages of One Way Vision?

The biggest advantage of the process is that it allows viewing the outside from inside on glass surfaces. With material thickness of 0.15 to 0.20 mm, if installed by an expert team, quite satisfactory results can be achieved. Also, the stronger the adhesive of the material used and the smaller the diameter of the perforations, the better the image quality will be. It is made from a material that is as thin as it is durable, making it very capable of maintaining its form and security.

In one-way vision printing, like all outdoor posters, latex and UV-based inks are used. Latex and UV-based inks are the most resistant to external factors. Considering that a text installed outdoors will be exposed to elements like rain, snow, and intense sunlight, if a durable ink is not used, the text may run or its colors may fade. Latex and UV-based inks prevent these situations. Additionally, factors like the quality of the product used and the experience of the installation team contribute to a lifespan ranging from 1 to 5 years.

One-way vision printing is generally used on buildings. This application, which can be seen almost everywhere recently, allows you to both make the insides of glass buildings invisible and advertise your business through digital printing on perforated PVC. Wraps are made by printing your desired text or photo in high quality. This technique is used not only on buildings but also on vehicles.

Reviews

There are no reviews yet.